In today’s fast-moving world of engineering and production, countless items we rely on every day—door hinges, smartphone frames, kitchen appliances, vehicle components—are made with stunning precision and speed. Yet behind this smooth flow of manufacturing stands a silent hero many people never think about: the Press Tool. This essential device is the backbone of high-volume metalworking, shaping raw materials into clean, accurate, and repeatable forms faster than any manual method ever could.

Though often overlooked, the press tool has become one of the most influential elements of industrial innovation. Its role extends far beyond stamping parts; it is the technology that keeps modern production lines efficient, sustainable, and cost-effective.

What Exactly Is a Press Tool?

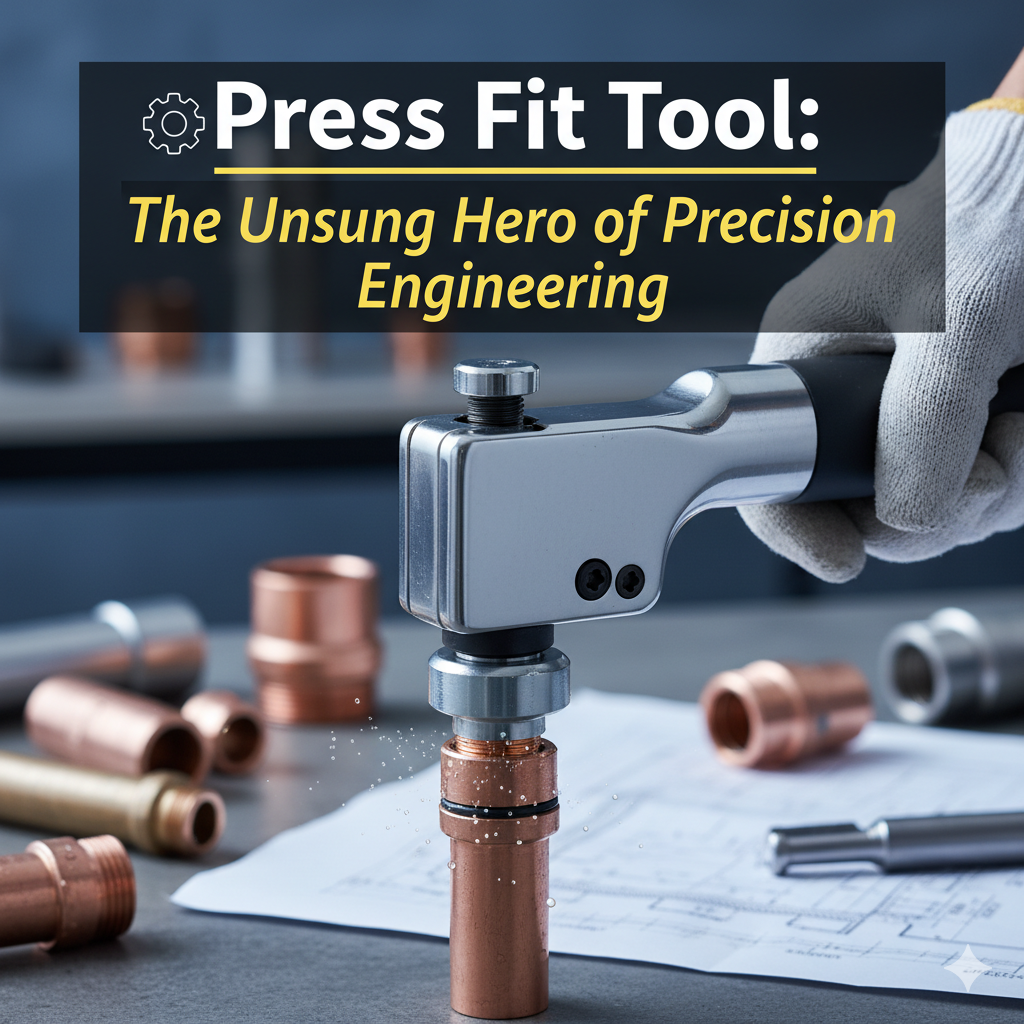

A Press Tool is a specialized mechanical device used to cut, shape, form, or finish sheet metal using controlled compression. When placed inside a press machine, it transforms a flat sheet into a precisely engineered component through processes such as punching, bending, blanking, drawing, and embossing.

In simple terms, a press tool is like a mold that works under force — but instead of molten material, it shapes solid metal sheets with absolute accuracy. Each tool is designed with a specific purpose in mind, which is why factories often keep dozens or even hundreds of them for different product designs.

Why Press Tools Matter in Modern Production

Manufacturers choose press tools because they deliver something incredibly valuable: consistency at scale. Whether a company needs 1,000 parts or 10 million, a well-designed press tool ensures that each piece looks and performs exactly the same.

Here’s what makes the press tool so important:

1. Lightning-Fast Output

Press tools allow manufacturers to produce thousands of identical components per hour. This speed makes them ideal for industries such as automotive, electronics, aerospace, and home appliances.

2. High Precision Every Time

A press tool’s design includes extremely tight tolerances. Once set up correctly, it produces parts with perfect uniformity—something crucial when components must fit seamlessly into complex assemblies.

3. Longer Tool Life

Press tools are made from hardened steel, carbide, and other durable materials, enabling them to withstand millions of cycles with minimal wear. This longevity dramatically reduces production costs.

4. Minimal Material Waste

Their precise cutting and shaping minimize scrap metal, making the production process cleaner, eco-friendly, and more cost-efficient.

Types of Press Tools Used in Industry

Over the years, engineers have designed different kinds of press tools to handle specific operations. Each type contributes in its own way to the manufacturing puzzle.

• Blanking Tools

Used to cut a clean piece of metal out of a sheet. The cut piece is the final product, shaped perfectly in a single stroke.

• Piercing Tools

These tools create holes or cut-outs in the metal sheet. When you see a product with perfect circular or square holes, a piercing press tool likely made them.

• Bending Tools

Used to fold metal into angled shapes. From cabinet hinges to structural brackets, bending tools form the backbone of many everyday metal products.

• Forming and Drawing Tools

These stretch or compress metal sheets to create curved or deep shapes. Automotive body panels, beverage cans, and cookware are often produced this way.

• Progressive Tools

One of the most advanced categories, progressive press tools perform multiple actions in a single run. As the sheet moves through the tool, each station carries out a different step—cutting, bending, shaping—until the completed part emerges.

The Future of Press Tools: Smarter, Faster, Greener

As industries embrace automation and AI-driven production, press tools are evolving too. Smart sensors are now being integrated directly into tools, helping detect wear, track performance, and prevent downtime. Advanced materials like carbide composites extend tool life even further, while eco-friendly lubricants reduce environmental impact.

Future press tools will be:

-

More energy-efficient

-

Digitally monitored

-

Designed with sustainable manufacturing principles

-

Optimized using AI simulation

All of this will help manufacturers maintain ultra-high production rates while reducing waste and improving quality.

Conclusion

A Press fit Tool may not be the flashiest part of the manufacturing ecosystem, but it is one of the most indispensable. It is the silent engine that shapes the metal world around us—efficient, precise, durable, and endlessly adaptable. As technology advances, press tools will continue to be at the heart of innovation, delivering the components that keep industries moving forward.